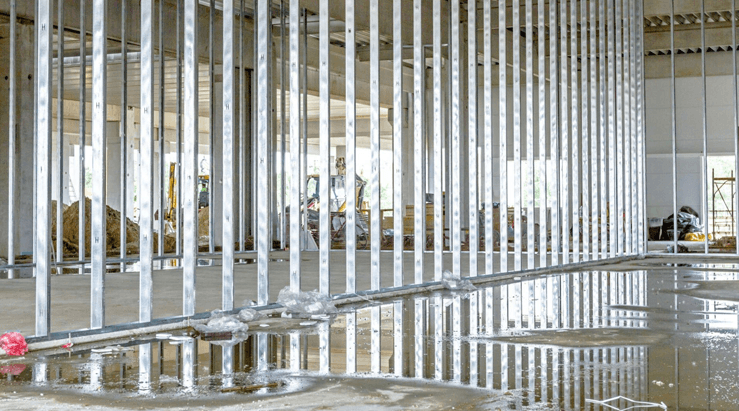

Dry Wall Partitioning System

The GTI Drywall Partitioning System is a range of vertical metal studs combined with ceiling and floor tracks that form a frame onto which drywall or plasterboards can be placed. This stud and track system is available in several widths, and have been tested to meet fire, acoustic and structural standards. A particular feature of the studs is their knurled flange surface, which allows for easier and faster screwing of drywalls using drywall screws. This allows the contractor to complete drywalls with the minimum amount of effort

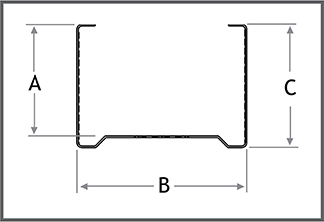

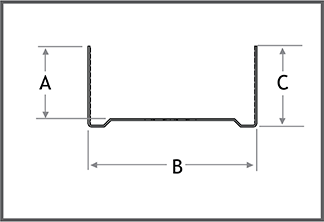

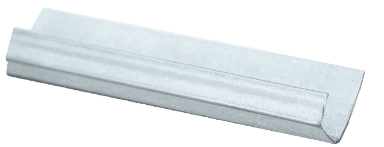

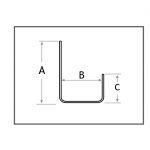

Stud

| Reference | Dimensions(AxBxC)(mm) | Thickness(mm) | Length(mm) | Material |

| GTIS 40 | 34 - 40 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 50 | 34 - 50 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 60 | 34 - 60 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 63 | 34 - 63 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 70 | 34 - 70 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 73 | 34 - 73 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 75 | 48 - 75 - 50 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 90 | 34 - 90 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 98 | 34 - 98 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 100 | 48 - 100 - 50 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 123 | 34/48 - 123 - 36/50 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 148 | 34 - 148 - 36 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 150 | 48 - 150 - 50 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

Other sizes of Length, Depth & Flange can be made upon request.

Depth 100mm upto 300mm, Thickness 1mm upto 3mm, Flange maximum 60mm.

- Material Standard: Galvanized Iron-BS EN 10346:2009 (formerly BS EN 10142:1991).

Coating Type: as per ASTM A653 / A653M. - Manufacturing Standard : BS EN 10162 : 2003 / BS EN 14195 : 2005

- ASTM C645 / C645 M.

- Length can be made up to 13 Meters.

- Flange height can be made upto 50mm.

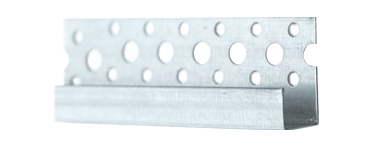

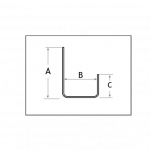

Track

| Reference | Dimensions(A-B-C) (mm) | Thickness | Length(mm) | Material |

| GTIS 42 | 25 - 42 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 52 | 25 - 52 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 62 | 25 - 62 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 65 | 25 - 65 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 72 | 25 - 72 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 75 | 25 - 75 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 77 | 38 - 77 - 40 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 92 | 25 - 92 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 100 | 25 - 100 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 102 | 38 - 102 - 40 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 125 | 25/38 - 125 - 25/40 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 150 | 25 - 150 - 25 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

| GTIS 152 | 38 - 152 - 40 | 0.45-1.5 | 3000 | Galvanized Iron (GI) |

Other sizes of Length, Depth & Flange can be made up on request.

Depth 100mm upto 300mm, Thickness 1mm upto 3mm, Flange maximum 70mm.

- Material Standard: Galvanized Iron-BS EN 10346:2009 (formerly) BS EN 10142:1991).

Coating Type: as per ASTM A653 / A653M. - Manufacturing Standard, : BS EN 10162 : 2003 / BS EN 14195 : 2005

ASTM C645 / CA645 M. - Flange height can be made upto 50mm

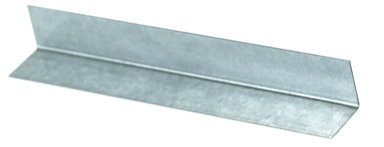

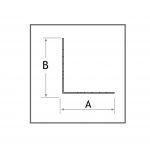

Drywall Angle Bead Plain

| Reference | Dimensions(A - B) | Thickness | Length(mm) | Material |

| GTIDAB30 | 30 - 30 | 0.45 | 2400/3000 | Galvanized Iron (GI) |

- Thicknesses and custom lengths are available upon request.

- Material Standard: Galvanized Iron (GI) – BS EN10346:2009

(formerly BS EN 10142:1991). - Coating Type: as per ASTM A653 / A653M

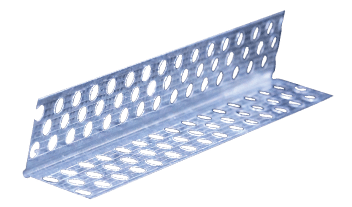

Drywall Angle Bead Perforated

| Reference | Dimensions (A-B) (mm) | Thickness (mm) | Length (mm) | Material |

| GTIDAB30 | 30 - 30 | 0.45 | 2400/3000mm | Galvanized Iron (GI) |

- Thicknesses and custom lengths are available upon request.

- Material Standard: Galvanized Iron (GI) – BS EN10346:2009

(formerly BS EN 10142:1991). - Coating Type: as per ASTM A653 / A653M

Drywall Edge Bead Plain (J-Bead)

| Reference | Dimensions (A-B-C) (mm) | Thickness(mm) | Length(mm) | Material |

| GTIDAB30 | 24 - 13 - 9 | 0.45 | 3000 | Galvanized Iron (GI) |

| GTIDEB15 | 24 - 15 - 9 | 0.45 | 3000 | Galvanized Iron (GI) |

- Thicknesses and custom lengths are available upon request.

- Material Standard: Galvanized Iron (GI) – BS EN10346:2009

(formerly BS EN 10142:1991). - Coating Type: as per ASTM A653 / A653M

Drywall Edge Bead Perforated (J-Bead)

| Reference | Dimensions(A-B-C) (mm) | Thickness(mm) | Length(mm) | Material |

| GTIDEBP13 | 24 - 13 - 9 | 0.45 | 3000 | Galvanized Iron (GI) |

| GTIDEBP15 | 24 - 15 - 9 | 0.45 | 3000 | Galvanized Iron (GI) |

- Thicknesses and custom lengths are available upon request.

- Material Standard: Galvanized Iron (GI) – BS EN10346:2009

(formerly BS EN 10142:1991). - Coating Type: as per ASTM A653 / A653M

Installation

Installation Steps

Step 1

INSTALL TRACKS

Install the tracks on the floors, ceilings and columns

where the drywall will be adjoined.

Step 4

Install studs

Install steel studs in the size and spacing indicated:

• Single-Layer Construction: Maximum space studs 600.0mm on center (unless otherwise indicated)

Multiple-Layer Construction: Maximum space studs 600.0mm on center (unless otherwise indicated).

Step 2

Adjust height

Extend partition framing to its full height to structural

supports or substrates above suspended ceilings,

except in places where partitions should terminate at

or just above suspended ceilings. Frame over doors

and openings and frame around the ducts that will

penetrate the partitions above ceiling to provide

support.

For fire-resistance rated partitions, extend height so

that the partition continuous from the floor to the

underside of the structure above. Install bridging if

required.

Step 6

Install Drywall

1. Install appropriate type of boards.

2. Make sure boards have the correct side facing

outward.

3. Use the maximum practical board size to minimize

joints.

4. Ensure board surfaces are aligned accurately.

5. Use self-drilling power screws to fix boards to studs

and tracks.

6. Start fixing the boards from center working towards

the edges and corners.

7. Provide angle beads at external corners and push

boards fully and corners.

8. Use continuous lengths of jointing tape set on jointing compound to fill gaps between boards and cover joints.

9. To have a smooth surface, apply additional compound to board concealed joints, the heads of fixings and imperfections in the face.

10.Finish by using primer or sealer on the surface.

Step 3

Brace frames

For partition frames that do not extend to the

structure above, brace it with studs of the same size and thickness.

Provide bracing at:

• 150.0mm on center intervals along the length of the partitions.

• Not less than 150.0mm on center from partition ends and corners.

• Door and window openings.

Features