STEEL CHANNEL LINTELS

GI Steel Lintels are used to replace conventional casting of concrete lintels over door and window apertures. The Designs of GTI Steel Lintels varies as per span. GTI manufacture different type of Lintels with different lengths.

GI Steel Lintels provide a combination of strength and are lightweight, resulting in efficient load bearing performance for all type of blocks and increased productivity for project requirements. They are characterized by their ease of installation.

GTI “GI Steel Lintels” are designed and fabricated as stipulated per project requirements.

GI Steel Lintels are manufactured to meet all kind of project requirements and comply with the international standards.

GTI Steel Lintels are manufactured in accordance with BS EN 845-2:2013+A1:2016 Relevant standards BS 5977 Part 2:1983

Finishing: Galvanized steel according to BS EN 10346:2015 | Hot Dipped Galvanized according to BS EN ISO 1461:2009 | Other or special coatings are available upon request.

Material : Cold rolled steel DC01 as per EN 10130:2006/ASTM A 1008 CS Type A/B (formerly ASTM A-366)

| Reference | Thickness (mm) | Height of Flange (mm) | Width of Lintel (mm) | Safe working load uniformly distribute | ||||

| 0.9-1.2 | 1.30-1.50 | 1.60-1.80 | 1.90-2.10 | 2.20-2.40 | ||||

| GTILIN 100H50 | 2.0 | 50 | 100 | 0.55 | 0.42 | 0.31 | ||

| 2.5 | 50 | 100 | 0.88 | 0.58 | 0.38 | 0.24 | 0.18 | |

| 3.0 | 50 | 100 | 0.93 | 0.60 | 0.4 | 0.29 | 0.21 | |

| GTILIN 100H75 | 3.2 | 75 | 100 | 1.63 | 1.25 | 1.00 | 0.86 | 0.64 |

| GTILIN 150H50 | 2.0 | 50 | 150 | 0.48 | 0.37 | 0.27 | ||

| 2.5 | 50 | 150 | 0.76 | 0.58 | 0.41 | 0.27 | 0.19 | |

| 3.0 | 50 | 150 | 1.15 | 0.74 | 0.48 | 0.37 | 0.64 | |

| GTILIN 150H75 | 3.2 | 75 | 150 | 1.63 | 1.25 | 1.00 | 0.86 | |

| GTILIN 200H50 | 2.0 | 50 | 200 | 0.62 | 0.48 | 0.35 | ||

| 2.5 | 50 | 200 | 0.77 | 0.59 | 0.41 | 0.29 | 0.21 | |

| 3.0 | 50 | 200 | 0.98 | 0.75 | 0.49 | 0.35 | 0.26 | |

| GTILIN 200H75 | 3.2 | 75 | 200 | 1.63 | 1.25 | 1.00 | 0.86 | 0.64 |

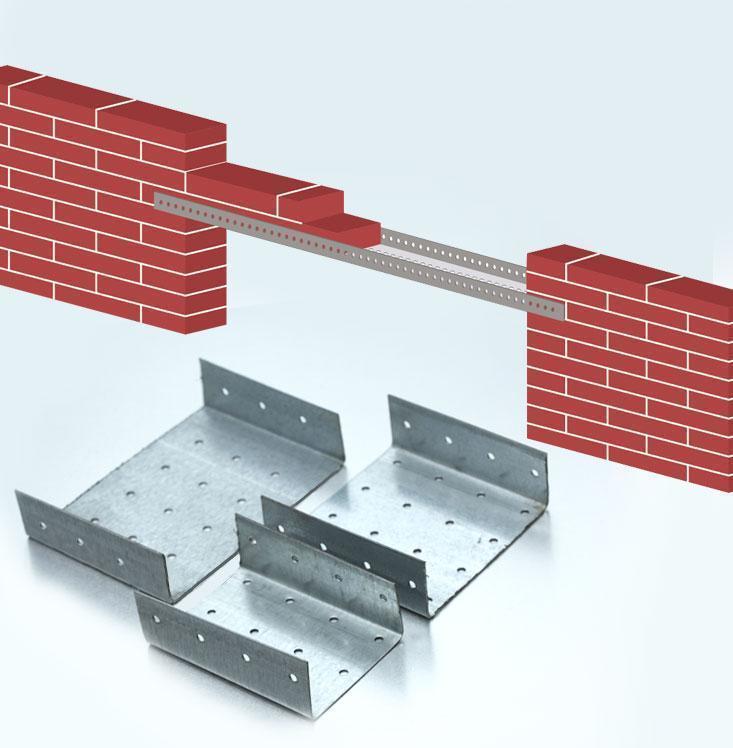

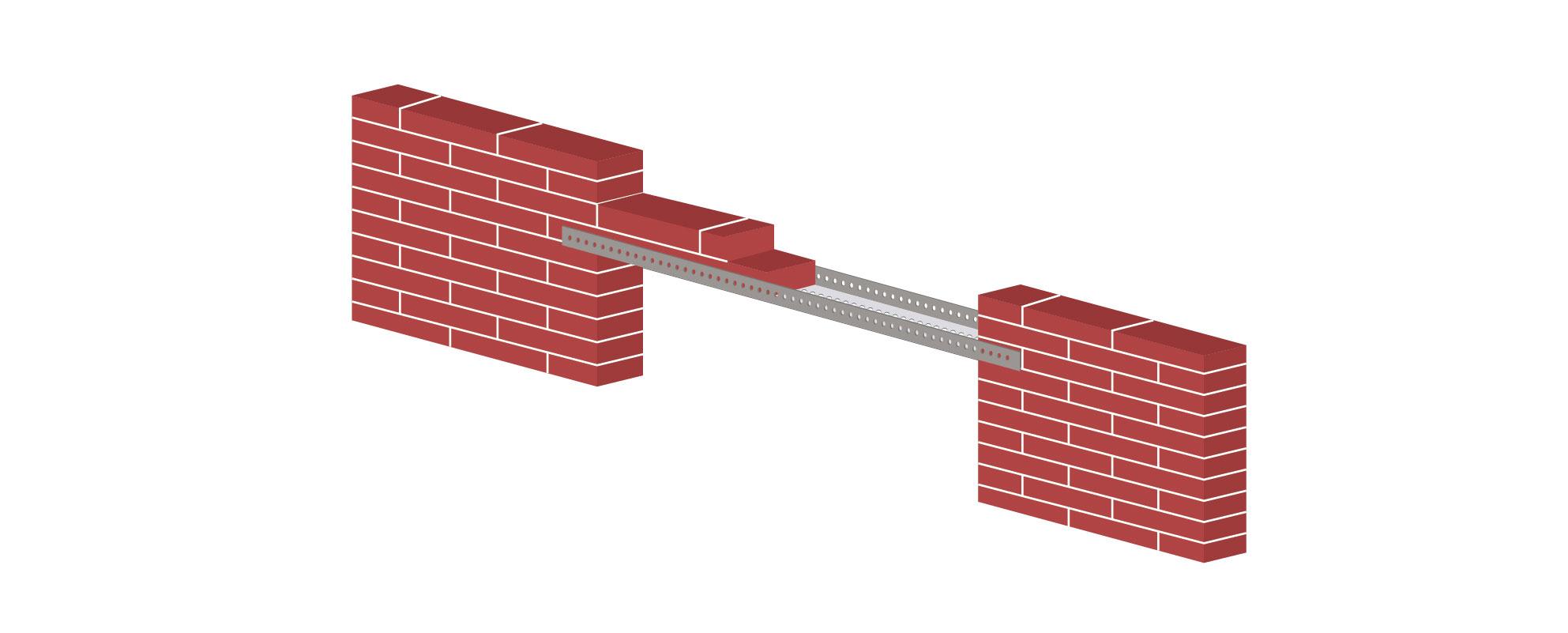

Installation

Step 1

Lintels must have a minimum end bearing of 150mm on each side of the opening, bedded on mortar. (150mm bearing for opening below 1.8meter and 200mm for opening above 1.8meter)

Step 2

The Lintel should be in level along its length and across its width. Masonry built must be laid on a mortar bed and all perpendicular joints to be filled with mortar. Masonry wall is laid in a running bond.

Step 3

Temporary support beneath the steel lintel is required to facilitate speed of construction to avoid shock loading when doing masonry work above it and to prevent high deflection.

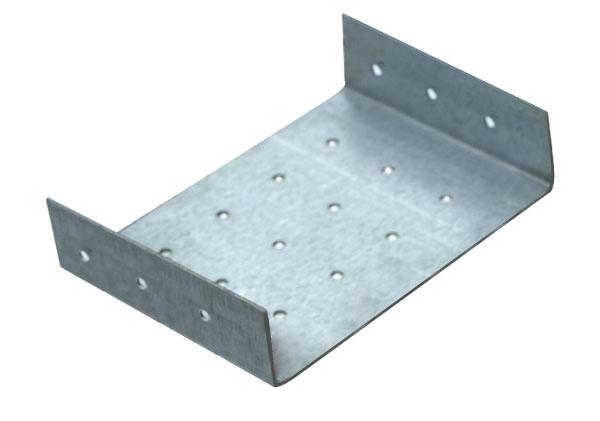

Step 4

The bracket can be used for bearing of Lintel when the wall is not present for bearing purpose.

Step 5

Lintel brackets are provided with fifixing holes to suit the expansion anchor sizes required.

Procedures

- Lintels shall be simply supported at each solid base using a minimum end bearing of 150-200mm.

- Lintels should not be cut to length or used if damaged or welded.

- Lintels must always be used within their weight capacity or other size suggested as per project requirements.

- Keep Lintel in level along its length and across its width. Masonry built must be laid on a mortar bed. Masonry wall is laid in running bond.

- Use support at center until mortar is dry to avoid high deflection and temporary shoring must be provided until masonry cured sufficiently to ensure the arching action.

- If wall is not present for bearing at another end of the Lintel, then use bracket of the same width of Lintel width for bearing, provided with fixing holes to suit the expansion anchor sizes required.

Note

- Special widths are available upon request.

- Other or special coatings are available upon request.

- Load calculation can be provided as per client request along with the different parameters to be provided for (size of block, density of block, density of plaster and plaster thickness as required).